Upholstered furniture has always been an indicator of luxury and comfort. It allows you to enjoy the comfort of home in a comfortable setting. One of the most important elements of furniture products is a sofa. He is able to replace the bed, act as a bed for rest by the TV or fireplace, serve as the subject of zoning of space. Without it, it’s difficult to imagine the interior of many rooms, whether it’s a living room, a director’s office or a work room designed for mental activity.

Manufacturers produce various designs, from standard stationary options, to corner and rounded models. They can act as an independent subject, equipped with a set of chairs, footrests. However, it is not always possible to choose a finished product that meets the requirements. For example, the buyer may not be satisfied with the color of the material used, its quality, or overpriced.In this case, you can make a sofa with your own hands, which will allow you to get the desired thing and save the family budget.

Content

Features of making a sofa with your own hands

Creating upholstered furniture will require a person to have minimal woodwork skills, as well as a tool for working. The process of self-fabrication of the structure begins with drawing up a diagram, preparing the necessary materials, tools. In order for the product to meet the requirements put forward by it, it lasts a long time, it looks aesthetically pleasing, certain rules must be observed:

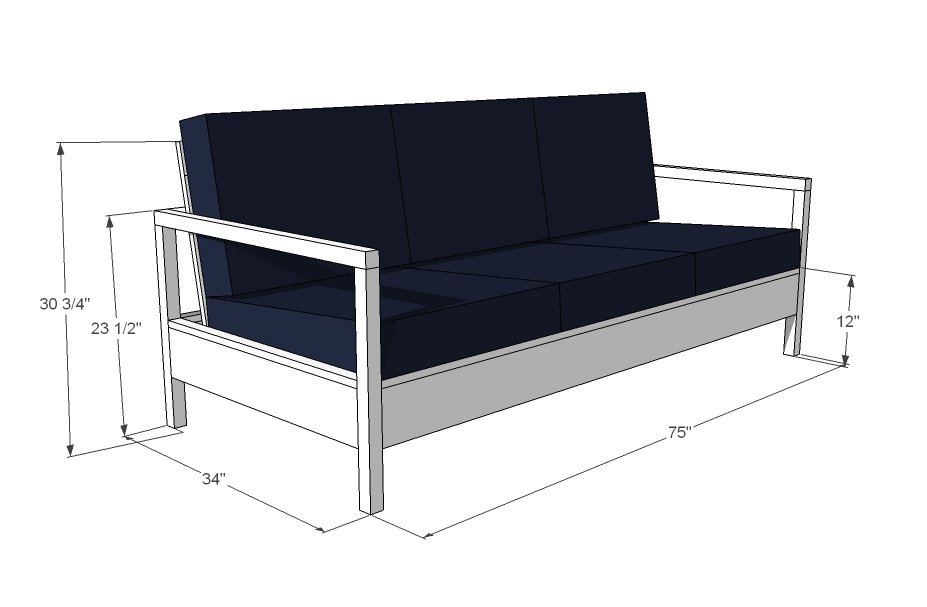

- When making a sofa with your own hands, you need to make a sketch of the product. If you don’t have drawing skills, you can use a ready-made plan downloaded on the net, taken in specialized literature. In the absence of experience in the creation of such products, it is better to use simple forms, which will reduce the time spent on work, reduce the amount of required raw materials.

- The chosen design should be convenient, functional, stylish.

- Do not save on components. The material for the frame should be high-quality and durable, the filler should be of the highest grade, the upholstery fabric should be wear-resistant, and should consist of strong fibers.

- Having decided on the design, having prepared all the components, you can start assembling.In order for the finished product to last for many years, it is necessary to carefully consider the process and observe the technology exactly.

The color of the paneling, the texture of the furniture should match the style of the room.

The advantages and disadvantages of homemade sofas

Self-assembly is characterized by a lot of positive aspects. Development takes place on the basis of our own ideas, which allows us to create a unique, individual design, the dimensions of which will exactly correspond to the room. At the same time, a self-made sofa has many advantages:

- The product will cost its owner much cheaper than purchased analogues, which will help save money.

- In the process of production, a person gains experience. Learning how to do the job, he can easily repair such structures, haul the canvas, and assemble more sophisticated furniture.

- At the design stage, you can determine the design of the planned product yourself, arrange it in full accordance with the interior style of the room.

- For work, no special tools or special conditions are required. Ordinary tools are suitable, and assembly can be done directly in the apartment or in the courtyard of a private house.

- Self-control of product quality will create a solid product.

- Own sofa will be the subject of pride of its owner, whom guests will be surprised.

Do not save on materials. The finished product and so will cost much cheaper than purchased in the store, and poor-quality components can lead to inconvenience during operation, short life.

Among the shortcomings of such products, it can be distinguished that without sufficient experience it is impossible to manufacture complex structures. Also, the process is time consuming, time consuming. If technology is not followed, the design may prematurely fail.

Options for making sofas

You can get an original piece of furniture at a minimum price if you make it yourself from readily available materials. Before starting work, you must select the appropriate model and assess the degree of complexity of the assembly. The design of any sofa is significantly different from a regular bed, it involves the presence of a stationary backrest, armrests. For the manufacture of any frame will require an accurate drawing. First of all, you should decide on the type of frame, material and set of functions.

From pallets / pallets

Unusual objects in the home environment, apartments create a modern, fashionable interior. A sofa from pallets or pallets will fit into any style of the room, but it will look most successfully in an eco-design. Having done a unique thing yourself, you can not only save well, but also give any room a unique atmosphere. A sofa made of knocked down wooden boards looks great in the hall, hallway, kitchen, on the terrace.

In addition to interior design, the sofa from pallets is very functional. It is convenient to use. Having made a seat of soft foam and pillows, it is easy to turn it into another berth. You can get additional shelves for storing household items, if you cover a sheet of plywood partitions.

Furniture should be in harmony with the interior of the room and soft details. If the ottoman is painted with varnish, it is better to decorate it with textiles that mimic the texture of burlap, you can use bright, checkered seats. To a monophonic dark framework bright pillows will approach. A sofa made of pallets in the country will look like home if you make upholstery with a floral print.

Of wood or timber

Natural wood furniture is very popular. Frames are made from a variety of breeds. It can be expensive oak, beech, birch, walnut or budget pine. Sofas made of timber are massive, strong, durable, have a noble appearance.

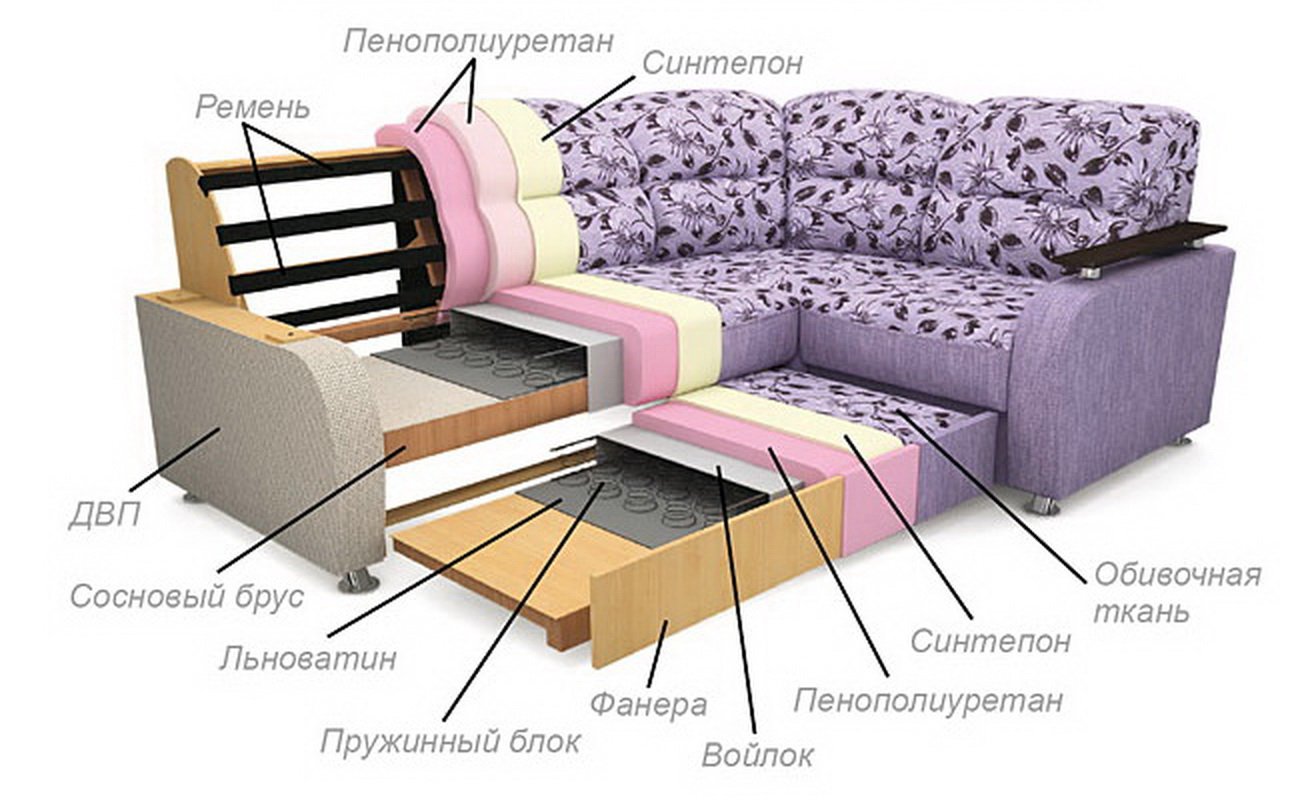

There are many schemes with various forms and methods of upholstery for beginner furniture makers, according to which you can easily create a real masterpiece. The main components of a bar sofa are the following elements:

- Back. The shape can be sloping, rectangular. More often it is made hollow inside;

- Wireframe. Collected from battens and timber. Increase rigidity with fiberboard sheets;

- Cladding. Perform on pre-harvested patterns. If the wood is of poor quality, its defects should be hidden under the upholstery;

- Armrests. Must be identical design with back. Can be made straight and stiff, upholstered in leather, cut out any pattern with a jigsaw.

From plywood

Natural, safe plywood has high wear resistance and is undeservedly considered by many furniture manufacturers to be inferior material. It is easy to make an exclusive sofa out of it yourself, enjoying the creative process and amazing results. Plywood is easy to use, it is easy to cut, bend. The sheet can be given any shape without fear that it will deform or break.

There are a lot of options for making sofas from plywood. To assess your abilities and skills, before preparing for a serious project you can practice and make a children's mini-sofa. The bulk of the materials can be found in any garage, barn, on the balcony. To work, you will need three crates and plywood sheets.

Having prepared the dimensions of the workpieces according to the drawing, we proceed to the assembly. You can connect parts in two ways - by gluing the drawers or leaving the drawers. Then we cover the frame with a cleaned plywood sheet, fix it, cover it with a mattress. The children's ottoman can be pushed against the wall and made the back of bright pillows. Low legs will give the design a more complete look.

From a profile pipe

The sofa from the profile pipe is a durable, original design that is guaranteed to last for decades.This frame is universal, resistant to mechanical stress. The blanks can have an oval, square, rectangular section. Due to the variety of shapes, you can give the finished product a very different design.

To make a long sofa from a loft-style profile, you will need several pipe cuts with a square section, metal corners, edged boards. Billets should be cut in advance to size, sanded irregularities and make the necessary holes. Then they are degreased and coated with a protective agent.

The assembly of the sofa can take place by welding or bolting. Following the step-by-step instructions, you need to start by connecting the frame, installing the legs, back. At the final stage, lamellas and crossbars are laid. From below it is possible to fasten roll-out boxes. You can decorate the sofa with minimalist paint or sheathe wood, textiles.

From metal and metal profile

On a metal frame, you can create a very light and compact sofa. The choice of design depends entirely on the personal preferences of the master. As a basis, you can take a regular metal profile. It is easy to assemble, easily bends without damage. Material breaks less frequently and is easily repaired. The advantages of the design include fire resistance, and the disadvantages are high weight.

For the veranda or terrace, you can make an original forged sofa. Self-production will require certain skills in working with material and equipment. The back and seats can be covered with leather cushions.

Upholstered frame

The base of the sofa can be made of a variety of materials. You can highlight and ennoble a piece of furniture with the help of upholstery. The choice of material is very large, so it should be taken into account when buying some factors, its purpose. The microclimate in the room. If the sofa will be a gathering place for good friends, the fabric should be durable, resistant to general wear and tear.Families with small children and pets are better off giving up expensive, delicate care products.

All upholstery material for frame sofas is divided into 9 groups (from 0 to 8), depending on the strength, the presence of natural fibers, the complexity of finishing and pulling. The following materials are most popular:

- Velours. Soft, pleasant to the touch. It is made on a natural basis;

- Flock. Non-woven textiles are resistant to detergents, animal claws;

- Jacquard. Lint-free material is durable and safe. Has a high price;

- Tapestry. It features a characteristic weaving, often performed in a landscape style;

- Chenil. Hard, cold stuff. Accepts only dry cleaning;

- Leather. Often used to cover office sofas. Smooth, slippery matter will last for many years;

- Boucle. Nodules with a dense structure, protruding on the surface, resemble the skin of a sheared lamb;

- Arpatek. Reminds skin, made of viscose, polyurethane, cotton.

From chipboard or laminated board

Particleboard furniture is not reliable and durable. But for a small children's sofa or modular design is quite suitable. It is necessary to work with the material with extreme caution, since its other negative characteristic is fragility and brittleness.

Assembly of the modular design begins with the armrests. It is these, the smallest details that need special attention. To make them perfectly smooth, symmetrical, you must clearly follow the drawing and carefully cut out the size of the laminated boards. Self-tapping screws are used to connect parts.

The next step is the assembly of the base. Boards are stuffed on two sides of a chipboard sheet and attached to the bar structure for fastening the backrest. Additionally, joints can be strengthened with carpentry glue. The resulting frame is upholstered in plywood and fabric lined with foam.

From MDF

MDF boards are easy to operate, amenable to a variety of processing methods. They are often used to make sofas, couches, and children's furniture. The material is resistant to dirt, easy to clean. You can place a homemade item on the veranda, in the kitchen, in the hallway. You can give it any shape, because the sheets lend themselves perfectly to milling.

The frame of MDF is assembled according to the standard principle. As legs, you can use freestanding solid parts and make ledges of the plate on both sides. Cover it with a soft mattress. The back can be left straight or curly.

From old chairs

Many economical and thrifty owners do not get rid of old furniture. Such items are sent for storage in the garage or on the balcony. From several chairs of the grandmother's headset, you can create an excellent modern sofa. There are several build options:

- For work, you will need four chairs with curved backs, screws, varnish. We disassemble two objects, the remaining legs are sawn off the front legs. We remove the old varnish coating with sandpaper from all the working elements of the future design. We attach dismantled crossbars from the middle part to chairs without legs. Whole backs play the role of sidewalls. We cover the sofa with varnish and install multi-colored rails in place of the seats.

- From two chairs with straight backs you get a beautiful sofa in a textile cover. We remove the seats from them, fix them with adhesive tape, and return them to their place. If the backrests are with a large clearance, it can be filled with plastic bottles with tape. We sheathe the structure with foam rubber or synthetic winterizer, then with any lining fabric. Cover with a cover for beauty.

From tires

Such a miniature sofa made of tires fits perfectly into the interior of the garage, complementing the living room loft. To make it, you will need a large tire from the truck, wooden bars for the back, a sheet of plywood, foam, upholstery fabric.From a simple material at hand, you can make a soft textile sofa or leave the rubber in its original form and make a stylish and comfortable item.

The tire must be thoroughly washed and covered with a prepared circle of plywood. You can fix it with screws or put it on glue. We cover the rigid base with foam rubber and tighten with a cloth. A round ottoman can be left low or made on legs. For this, the wooden pieces from the pallet are suitable. The backrest is made of polished boards or bars. They can be covered with a cover or left as is.

Workshop on creating a frameless model

This design is lightweight, mobile, it does not scratch the flooring, and if defects occur, it is easily repaired. For work, you need foam rubber and strong furniture fabric. The manufacturing process begins with a drawing up. First you need to prepare the required materials and tools, namely:

- sewing machine, threads, needles;

- scissors, glue;

- measuring instruments, chalk;

- highly elastic PPU brand HR 3535, able to withstand the load on the mattress up to 120 kg;

- flock, lightning.

Let's take a step-by-step master class using an example of a folding sofa consisting of 4 pillows:

- From the standard sheet of HR 3535 foam rubber, the dimensions of which are 160x200x4 cm (length, width, height), we cut out the required size, for example, in the case under consideration 160x90x4 - the base, 160x60x4 - the second layer (seat), 160x30x4 - the second layer (backrest), 160x450x4 - back. To form pillows for each of these components, you need 6 sheets to get a sofa height of 50 cm.

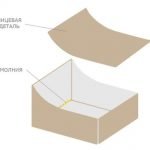

- We form pillows from the foam rubber, at the same time we glue the sheets together, we sew them with a lining fabric. This will allow them to maintain their shape, and it will also be easier to install them in a case.

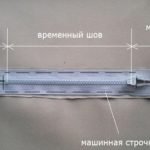

- We sew a cover from a flock. To do this, we make markings on the fabric corresponding to the dimensions of the pillows with an allowance of 1 cm, cut it into rectangles and stripes, sew it together. At the junction of the strips and one of the rectangles, we install a zipper.

- At the final stage, it remains to assemble all parts of the sofa together.It is necessary to think about how details will be connected at the planning stage. There are two main ways of attaching elements. They can be sewn inside out, stitching a double strip over the connection.

Workshop on creating a frame sofa

The product is intended for stationary installation. Differs in big weight from frameless analogs. May have a complex structure. Beginners in carpentry are encouraged to start with simple designs, which often turn out to be the most reliable and durable. To complete the work you will need:

- wooden beam 40x40 mm, 40 mm thick board, chipboard, plywood;

- fabric for lining, foam;

- screwdriver, drill, jigsaw;

- measuring instruments, glue, pencil;

- hammer, hacksaw, knife;

- fasteners.

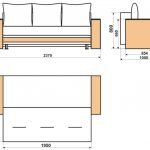

For an example, we’ll review the instructions for the simplest frame rectangular sofa:

- The frame will be made in standard dimensions: 190 cm - the length of the product, 80 cm - the height of the back, 30 cm - seat height excluding pillows.

- We proceed to cutting horizontal partitions. To do this, we cut out two slats 182 cm long from a board 4 cm thick, and another 6 - 86 cm long;

- From 4x4 cm boards we cut 4 vertical posts 76 cm long, 3 - 95 cm each, 1 - 182 cm. \ All wood must be treated with stains, impregnations, varnish, and painted if necessary.

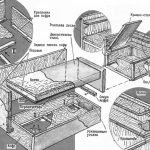

- After complete drying, we proceed to assembling the frame, using a screwdriver and self-tapping screws we connect all the elements with each other.

- After the frame is ready, we sheathe the seat and back with plywood, after which we paste over them with foam rubber.

- We wrap the design with synthetic winterizer, which will help hide defects, make the product softer.

- At the final stage, we cover the workpiece with a cloth, fixing it with an industrial stapler.

- You can make such a design with your own hands within a week.

Manufacturing a corner sofa with a retractable mechanism

The design of such a piece of furniture, although it has impressive dimensions, fits perfectly into any interior. Angled layout saves space.Creating an independent project has many advantages - the ability to choose the right quality material for the frame, the size of the structure.

It is better to make the basis of wood, a softwood beam, fiberboard, chipboard, plywood will do. To work at home, you will need a large space, a set of necessary tools (circular saw, furniture stapler, screwdriver).

Start work with the preparation of the drawing. Manufactured structural parts must be numbered and laid out on the floor. We begin the assembly with the largest parts, gradually adding. It is better to fasten a tree with screws and glue. To fix the lifting mechanism, it is necessary to drill holes in the bottom and screw the drawers. The finished structure is glued with foam rubber, agrotextile for tightening and upholstery.

Making a sofa book

The easy-to-use sofa model is very popular. In addition to boards, boards, MDF sheets and various consumables, you will need to buy transformation mechanisms for its assembly.

First of all, you need to prepare wood for the wooden frame of the book (seats, backs, armrests, drawers for linen). We twist the bars, reinforce with transverse rails, nail a sheet of plywood to the bottom. The resulting cells will be drawers in the sofa.

We begin the collection of the sliding base with the seat. You will need to make two identical designs with slats that will hold the mattress. We cut the armrests from the boards of the chipboard strictly according to the size of the drawing, then knock down the frame for them. When all the details are ready, you can proceed with the assembly of the folding Eurobook sofa and the installation of transformation mechanisms. It remains only to make it soft and stylish with foam rubber and upholstery.

Sofa from the old bath

An interesting and creative sofa can be made from an old bathtub. Functional decor will decorate any room. For manufacturing, a plastic, cast-iron, metal container is suitable.A particularly stylish sofa will turn out from old-style models.

In addition to the bath itself, an angle grinder, cutting wheels, enamel paints will be required for operation. First of all, it should be cleaned well, remove the cracked paint, rust. It is better to work outdoors, since there will be a lot of metal chips and dust during the grinding process.

We lay the cleaned bath on its side and draw with the marker the alleged outline of the frame. The depth of the recess and the width of the future sofa depends on personal preferences and the condition of the workpiece. The cut lines can be oblique, even, semicircular.

We cut the line with a grinder and we clean the edges from burrs. Now you can proceed to decorating the walls. For this, any paints for metal are suitable. As legs, you can use special overhead elements that fix themselves under heavy weight, wooden blocks, stone blocks. We make a seat from foam rubber in a cover and decorative pillows.

Conclusion

The sofa plays an important role in the interior of any house, apartment. Without it, it is difficult to imagine a room in which a comfortable rest is possible. Choosing upholstered furniture from manufacturers, it is not always possible to find options that meet all the requirements. Therefore, products manufactured independently can become an alternative to purchased goods. Such models will favorably differ from the sold analogues, serve as the subject of pride of the owner.

I’m looking at the mechanisms of sofa transformation only a dolphin or an eurobook - there’s nothing to break. I don’t recognize the rest.